CPVC vs PPR

FlowGuard® CPVC pipe and fittings are backed by more than 50 years of proven performance in various applications, with distinct advantages over polypropylene (PPR) or green pipe.

Since its arrival, PPR system failures are reported in diverse climates and regions due to poor installation, as well as damaged pipes caused by chlorine disinfectants used in potable water. These inadequacies have left some homeowners, plumbers and traders wondering which is the better material.

If you’re considering CPVC for your plumbing system, here are five areas where FlowGuard CPVC outperforms PPR.

Strong, Rigid Material

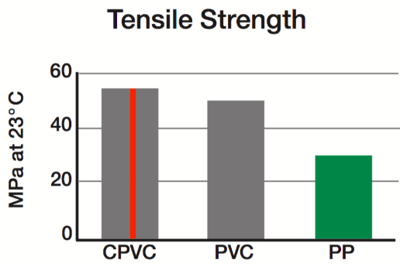

CPVC is a highly durable material. When directly comparing FlowGuard CPVC to PPR, our material has:

- 60% greater tensile strength.

- Nearly twice the flexural strength.

- A higher pressure bearing capability, which allows CPVC to have the same flow rate as PPR, but with a smaller pipe size.

Quicker, Cost-Effective Installation

Solvent cement welding is the recommended joining method for FlowGuard CPVC because it’s quick, simple, and highly reliable.

- The solvent welding process allows for quick and easy assembly.

- Unlike heat welding, if mistakes during installation occur, they can easily be corrected by removing the fitting, cleaning residual solvent cement from the pipe, and starting the installation process over again.

- The tools required are inexpensive and easy to use.

- Solvent cemented joints are the strongest part of the piping system.

- No heat is required for CPVC installation, so there is no fire or burn risk.

- Solvent cement allows for easy installation in tight, confined spaces.

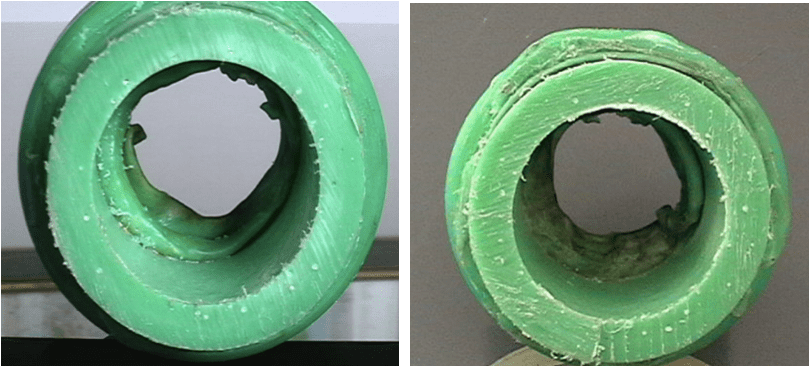

- PPR requires heat fusion to install. This leads to the likelihood of bead formation inside the pipe, which reduces flow rate and increases mineral deposits and bacterial growth.

Superior Water Quality

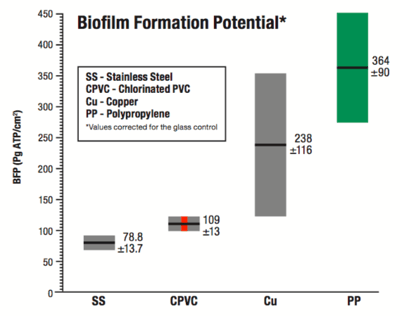

FlowGuard CPVC’s resistance to biofilm formation helps keep water pure by reducing the risk of:

- Accumulation of microorganisms which may cause health problems.

- Impaired water quality, including taste and smell.

- Bacterial growth, including multiplication of Legionella and Pseudomonas as well as increased counts of Coliform bacteria.

Multiple international studies confirm that CPVC consistently outperforms PPR, when it comes to resisting biofilm formation.

FlowGuard CPVC has been approved for potable water applications by major international agencies including:

In fact, FlowGuard CPVC holds an NSF 61 Annex G certification, which verifies the weighted average lead content within the piping material is less than 0.25%.

Greater Material Safety

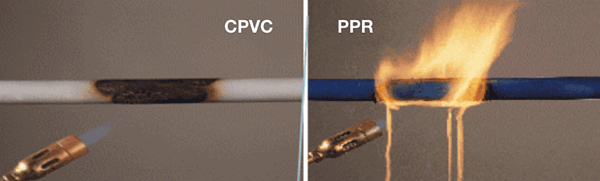

Limiting Oxygen Index (LOI) is the percentage of oxygen needed in the atmosphere to support combustion. The higher the value, the greater resistance to burning.

- CPVC has an LOI of 60 and does not support combustion.

- PPR has an LOI of 18, making it a combustible material that can increase fire damage when flaming drips fall from the pipe.

Chlorine Resistant

Depending on the material of your piping, common household disinfectants, like chlorine and chlorine dioxide, can damage pipes.

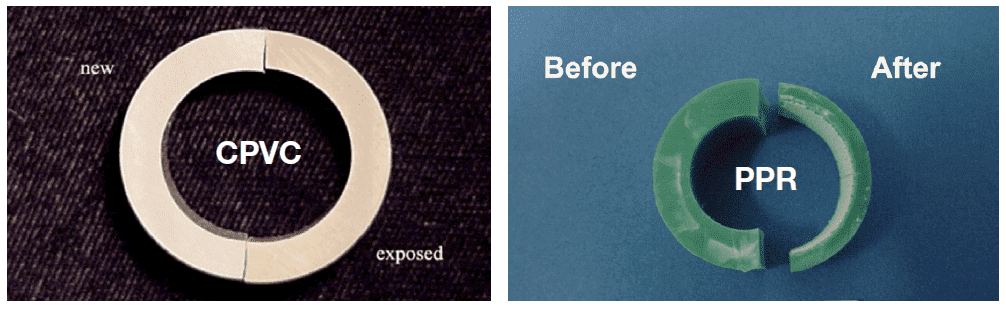

- PPR erodes in hot chlorinated water systems and is susceptible to oxidative stress cracking, causing pieces of the pipe to flake off and clog plumbing systems. Overtime, the system will lose its ability to hold pressure, resulting in leaks and sometimes system failure.

- FlowGuard CPVC is unaffected by chlorine and chlorine dioxide present in potable water supplies thanks to the additives used to keep your water clean and safe.

CPVC Compared to PPR Exposed to Chlorine

***PPR tested in general accordance with NSF P-171 Protocol for Chlorine Resistance of Plastic Piping Materials and ASTM F-2023-04 Test Method for Evaluating the Oxidative Resistance of PEX Tubing and Systems to Hot Chlorinated Water.